Rancang Bangun Alat Pengiris Tempe Dengan Menggunakan Penggerak Motor Listrik

DOI:

https://doi.org/10.55679/pistonjt.v10i2.124Kata Kunci:

Mesin tepat guna, Industri, Teknologi, Pelaku usaha, Makanan ringanAbstrak

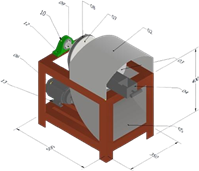

The development of the business world necessitates machines that can enhance business productivity, especially for players in the industrial sector, primarily Small and Medium Enterprises (SMEs). Therefore, appropriate technology machinery is required to support business development. The use of internal combustion engines is certainly inefficient in terms of fuel consumption and risks contamination with the resulting product. An electric machine becomes the main and practical choice to support the productivity of business actors. This Design of a Tempeh Slicing Tool Using an Electric Motor Drive aims to increase the efficiency and safety of the tempeh slicing process, which is generally done manually by SME actors. The machine is designed using an electric motor as the main drive, which rotates the cutting blade through a pulley and V-belt transmission system. Test results show that the tool can slice tempeh with a uniform thickness (2-3 mm) and an average time speed of 3 seconds per tempeh unit. The cutting success rate reached 95.7% for square-shaped tempeh, making the tool highly feasible for increasing productivity in the small-scale food industry.

Unduhan

Referensi

Sutardi, S. (2014). Tempe: Makanan Tradisional Kaya Nutrisi. Bandung: AgroMedia

Astari, D. (2019). Kandungan Gizi Tempe dan Manfaatnya Bagi Kesehatan. Jakarta: Pustaka Nutrisi.

Fitria, N. (2010). Studi Efisiensi Alat Pemotong Tempe pada Industri Rumah Tangga. Jurnal Teknologi dan Industri, 7(1), 12–18.

R. A. Himarosa, S. Sudarisman, A. Bisandyaloka, and F. Sofyantoro, “Pengembangan Unit Usaha Tempe melalui Aplikasi Mesin Giling Kedelai Teknologi Screw,” J. Pengabdi. Pada Masy., vol. 7, no. 2, pp. 298–307, 2022, doi: 10.30653/002.202272.72.

S. A. Muttalib, A. F. Hidayat, and A. Priyati, “Rancang Bangun Hopper Out Put Campuran Ragi Tempe Dengan Kedelai,” J. Ilm. Rekayasa Pertan. dan Biosist., vol. 7, no. 1, pp. 17–23, 2019, doi: 10.29303/jrpb.v7i1.99.

H. Hariri, M. Al Fathar, and I. Bachtiar, “Rancang bangun mesin pengiris tempe otomatis,” SINTEK J. J. Ilm. Tek. Mesin, vol. 16, no. 1, p. 30, 2022, doi: 10.24853/sintek.16.1.30-40.

B. M. T. Pakpahan et al., Elemen Mesin Untuk Elemen Mesin Untuk Teknik Industri Teknik Industri, Pertama., no. Desember. GET PRESS INDONESIA, 2023.

S. D. Yulianto, M. Ivanto, and M. Taufiqurrahman, “Rancang Bangun Mesin Perajang Keripik Tempe Dengan Mekanisme,” Teknol. Rekayasa Tek. Mesin, vol. 6, no. 1, pp. 8–14, 2025.

R. A. Himarosa, S. Sudarisman, A. Bisandyaloka, and F. Sofyantoro, “Pengembangan Unit Usaha Tempe melalui Aplikasi Mesin Giling Kedelai Teknologi Screw,” J. Pengabdi. Pada Masy., vol. 7, no. 2, pp. 298–307, 2022, doi: 10.30653/002.202272.72.

A. Saidah and A. Farudin, “Analisa Kinerja Mesin Pengiris Tempe Menggunakan Motor Penggerak 0,5 Hp Dengan Sistem Pendorong Otomatis,” J. Tek. Teknol. Terap., vol. 1, no. 1, pp. 31–35, 2023, doi: 10.47970/jttt.v1i1.431.

Unduhan

Diterbitkan

Cara Mengutip

Terbitan

Bagian

Lisensi

Hak Cipta (c) 2025 Sudarsono, Samhuddin, La Ode Ahmad Barata, Muhamad Laskar Wahid, Urzunil Kadim, Zulkifli Ananda

Artikel ini berlisensi Creative Commons Attribution 4.0 International License.