Studi Kekuatan Tarik Komposit Serat Sabuk Kelapa Antisymmetric Laminates

DOI:

https://doi.org/10.55679/pistonjt.v10i1.92Keywords:

Coconut sheath, Antisymmetric laminate, Tensile strength, Elastis modulus, Natural fiberAbstract

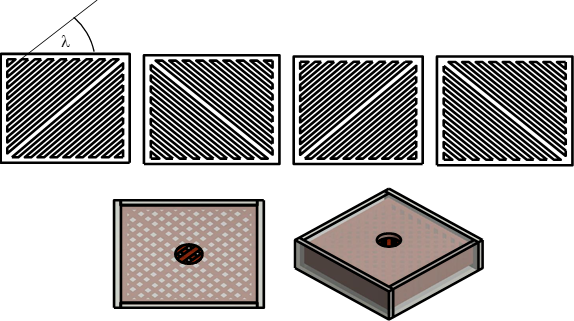

The utilization of natural fiber-based composite materials is increasingly developing as an environmentally friendly alternative to synthetic materials. Coconut sheath fiber is an agricultural waste with potential as reinforcement in polymer matrices due to its strength and flexibility. This study focuses on the tensile strength of coconut sheath fiber composites in antisymmetric laminate configurations, which have not been widely explored. Such configurations are expected to enhance mechanical performance, particularly in lightweight structural applications. The study aims to analyze tensile characteristics and understand the influence of laminate orientation on the mechanical properties of the composite. The problem addressed is how tensile strength behaves in coconut sheath fiber antisymmetric laminates with fiber orientations of [-45°/+45°/-45°/+45°] and [-30°/+30°/-30°/+30°]. A quantitative research method was used, consisting of the following stages: (1) fiber preparation, (2) fiber soaking, (3) mold fabrication, (4) composite fabrication, (5) specimen preparation, and (6) tensile testing. The results showed that the highest average tensile stress was obtained in the +45°/-45°/+45°/-45° orientation, with a value of 10.578 MPa, a tensile strain of 2.452%, and an elastic modulus of 0.004 GPa. The positive contribution of this study lies in revealing the potential of coconut sheath waste as a reinforcing material for composites with promising mechanical performance under specific laminate configurations. However, the study is limited in the range of fiber orientations explored and does not include evaluations under other mechanical loads such as bending and impact. Further studies are recommended to investigate a wider range of fiber orientations and to conduct multiaxial mechanical testing to obtain a more comprehensive understanding of the composite behavior.

Downloads

References

R. A. Nur, “Pengaruh Penambalan Fraksi Volume Pada Komposit Matriks Epoxi dan Nanopartikel Titanium Dioksida TiO2 Metode Open Molding Terhadap Sifat Fisik dan Mekanik Material,” Universitas Andalas, 2021.

A. Gavrila, B. Junipitoyo, and Linda Winiasri, “Uji Tarik Dan Uji Impact Pada Komposit Serat Sabut Kelapa Dengan Variasi Arah Serat,” Pros. SNITP, pp. 1–7, 2022, [Online]. Available: https://ejournal.poltekbangsby.ac.id/index.php/SNITP/article/view/1339%0Ahttps://ejournal.poltekbangsby.ac.id/index.php/SNITP/article/download/1339/1371

R. Damian, N. Bifel, E. U. K. Maliwemu, D. G. H. Adoe, and J. T. Mesin, “Pengaruh Perlakuan Alkali Serat Sabut Kelapa terhadap Kekuatan Tarik Komposit Polyester,” LONTAR J. Tek. Mesin Undana, vol. 2, no. 1, pp. 61–68, 2015, [Online]. Available: https://ejurnal.undana.ac.id/index.php/LJTMU/article/view/489

E. Putra, D. Boangmanalu, A. Qadry, F. Taruyun, H. Sinaga, and A. B. Pratama, “Sabut Kelapa,” vol. 05, no. 01, pp. 56–63, 2024.

N. Endriatno and L. O. A. Barata, “Ekstraksi Serat Alam Untuk Aplikasi Material Komposit Dengan Mesin Dekortikator,” Pist. J. Teknol., vol. 9, no. 1, pp. 7–14, Jul. 2024, doi: 10.55679/pistonjt.v9i1.54.

H. I. Firmansyah, A. Purnowidodo, S. A. Setyabudi, T. Mesin, and U. Brawijaya, “Pengaruh Mechanical Bonding Pada Aluminium Dengan Serat,” vol. 9, no. 2, pp. 127–134, 2018.

R. Magga, “Sifat Kuat Tarik Material Komposit Hibrid Berpenguat Serat Ijuk Dan Sabut Kelapa Dengan Orientasi Serat Acak,” J. Mek., vol. 10, no. 2, pp. 980–991, 2019.

Zulkifli, I. B. Dharmawan, and W. Anhar, “Analisa pengaruh perlakuan kimia pada serat terhadap kekuatan impak charpy komposit serat sabut kelapa bermatriks epoxy,” J. Polimesin, vol. 18, no. 1, pp. 47–52, 2020.

D. Siswanto, “Karakteristik serat kulit waru yang disusun laminasi bermatrik poliseter dengan orientasi serat (30, 35, 45 derajat) terhadap sifat fisis dan mekanis,” Universitas Muhammadiyah Surakarta, 2016.

I. Mawardi, A. Azwar, and A. Rizal, “Kajian perlakuan serat sabut kelapa terhadap sifat mekanis komposit epoksi serat sabut kelapa,” J. POLIMESIN, vol. 15, no. 1, p. 22, 2017, doi: 10.30811/jpl.v15i1.369.

ASTM, “Astm D3039/D3039M,” 2014. doi: 10.1520/D3039.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Samhuddin, Aminur, Sri Amrin Al Kadirun, La Ode Ahmad Barata

This work is licensed under a Creative Commons Attribution 4.0 International License.