Pengaruh Aditif Pelumas Hexagonal Boron Nitride terhadap Keausan Mesin Diesel B30 dalam Uji Durabilitas 200 Jam

DOI:

https://doi.org/10.55679/pistonjt.v10i2.118Kata Kunci:

Biodiesel , Gesekan , Nanopartikel , Performa Mesin , TribologiAbstrak

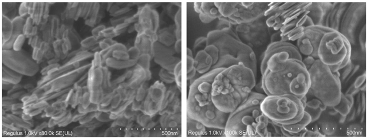

Hexagonal boron nitride (hBN) nanoparticles have emerged as a promising lubricant additive to mitigate friction and wear in internal combustion engines. This study presents a comprehensive experimental investigation of exfoliated hBN nanoparticles as a lubricant additive for a single-cylinder four-stroke diesel engine operating on B30 biodiesel fuel. A prolonged 200-hour durability test was conducted to evaluate the effects of hBN-additivated lubricant on engine wear characteristics and performance parameters, including torque, specific fuel consumption, and brake power. Wear analysis was performed on critical engine components to quantify wear reduction mechanisms. The results demonstrate that exfoliated hBN nanoparticles effectively reduce wear rates in B30-fueled diesel engines, contributing to enhanced tribological performance and extended engine durability. Furthermore, the additivated lubricant exhibited improved fuel efficiency without compromising engine performance. This work addresses a significant gap in the tribological literature regarding nano-additive efficacy in biodiesel combustion systems and provides practical insights for sustainable engine operation. The findings underscore the potential of hBN as a functional nano-additive in supporting both efficiency and environmental sustainability of biofuel-based internal combustion engines.

Unduhan

Referensi

H. I. Kim, J. Shon, and K. Lee, “A study of fuel economy and exhaust emission according to engine coolant and oil temperature,” Journal of Thermal Science and Technology, vol. 8, no. 1, pp. 255–268, 2013, doi: 10.1299/jtst.8.255.

K. Holmberg and A. Erdemir, “Influence of tribology on global energy consumption, costs and emissions,” Sep. 01, 2017, Tsinghua University Press. doi: 10.1007/s40544-017-0183-5.

K. Holmberg and A. Erdemir, “The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars,” Tribol Int, vol. 135, pp. 389–396, Jul. 2019, doi: 10.1016/j.triboint.2019.03.024.

J. Luo and X. Zhou, “Superlubricitive engineering—Future industry nearly getting rid of wear and frictional energy consumption,” Aug. 01, 2020, Tsinghua University Press. doi: 10.1007/s40544-020-0393-0.

G. Vaitkunaite, C. Espejo, B. Thiebaut, A. Neville, and A. Morina, “Low friction tribofilm formation and distribution on an engine cylinder tested with MoDTC-containing low viscosity engine lubricants,” Tribol Int, vol. 171, p. 107551, Jul. 2022, doi: 10.1016/j.triboint.2022.107551.

L. Guan, X. L. Feng, G. Xiong, and J. A. Xie, “Application of dielectric spectroscopy for engine lubricating oil degradation monitoring,” Sens Actuators A Phys, vol. 168, no. 1, pp. 22–29, Jul. 2011, doi: 10.1016/j.sna.2011.03.033.

Theo. Mang and Wilfried. Dresel, Lubricants and lubrication. Wiley-VCH, 2007.

M. S. Charoo and M. F. Wani, “Tribology in Industry Tribological Properties of IF-MoS 2 Nanoparticles as Lubricant Additive on Cylinder Liner and Piston Ring Tribo-pair,” 2016. [Online]. Available: www.tribology.fink.rs

W. Ahmed Abdalglil Mustafa, F. Dassenoy, M. Sarno, and A. Senatore, “A review on potentials and challenges of nanolubricants as promising lubricants for electric vehicles,” Lubrication Science, vol. 34, no. 1, pp. 1–29, Jan. 2022, doi: 10.1002/ls.1568.

A. Devaraj, M. Nagappan, D. Yogaraj, O. Prakash, Y. A. Rao, and A. Sharma, “Influence of nano-additives on engine behaviour using diesel-biodiesel blend,” Mater Today Proc, Apr. 2022, doi: 10.1016/j.matpr.2022.03.598.

J. Zhao, Y. Huang, Y. He, and Y. Shi, “Nanolubricant additives: A review,” Oct. 01, 2021, Tsinghua University. doi: 10.1007/s40544-020-0450-8.

P. Gangwani, M. K. Gupta, and J. Bijwe, “Synergism between particles of PTFE and hBN to enhance the performance of oils,” Wear, vol. 384–385, pp. 169–177, 2017, doi: 10.1016/j.wear.2017.01.053.

A. v. Bondarev, A. Fraile, T. Polcar, and D. v. Shtansky, “Mechanisms of friction and wear reduction by h-BN nanosheet and spherical W nanoparticle additives to base oil: Experimental study and molecular dynamics simulation,” Tribol Int, vol. 151, Nov. 2020, doi: 10.1016/j.triboint.2020.106493.

M. I. H. C. Abdullah, M. F. bin Abdollah, H. Amiruddin, N. Tamaldin, and N. R. M. Nuri, “Optimization of tribological performance of hBN/AL2O3 nanoparticles as engine oil additives,” in Procedia Engineering, Elsevier Ltd, 2013, pp. 313–319. doi: 10.1016/j.proeng.2013.12.185.

S. Shahnazar, S. Bagheri, and S. B. Abd Hamid, “Enhancing lubricant properties by nanoparticle additives,” Jan. 30, 2016, Elsevier Ltd. doi: 10.1016/j.ijhydene.2015.12.040.

A. Kotia, K. Chowdary, I. Srivastava, S. K. Ghosh, and M. K. A. Ali, “Carbon nanomaterials as friction modifiers in automotive engines: Recent progress and perspectives,” Jul. 15, 2020, Elsevier B.V. doi: 10.1016/j.molliq.2020.113200.

A. Tomala et al., “Synergisms and antagonisms between MoS2 nanotubes and representative oil additives under various contact conditions,” Tribol Int, vol. 129, pp. 137–150, Jan. 2019, doi: 10.1016/j.triboint.2018.08.005.

S. Shahnazar, S. Bagheri, and S. B. Abd Hamid, “Enhancing lubricant properties by nanoparticle additives,” Int J Hydrogen Energy, vol. 41, no. 4, pp. 3153–3170, Jan. 2016, doi: 10.1016/j.ijhydene.2015.12.040.

W. Dai, B. Kheireddin, H. Gao, and H. Liang, “Roles of nanoparticles in oil lubrication,” Tribol Int, vol. 102, pp. 88–98, Oct. 2016, doi: 10.1016/j.triboint.2016.05.020.

O. Tevet, P. Von-Huth, R. Popovitz-Biro, R. Rosentsveig, H. D. Wagner, and R. Tenne, “Friction mechanism of individual multilayered nanoparticles,” Proceedings of the National Academy of Sciences, vol. 108, no. 50, pp. 19901–19906, Dec. 2011, doi: 10.1073/pnas.1106553108.

M. Kalin, J. Kogovšek, and M. Remškar, “Mechanisms and improvements in the friction and wear behavior using MoS2 nanotubes as potential oil additives,” Wear, vol. 280–281, pp. 36–45, Mar. 2012, doi: 10.1016/j.wear.2012.01.011.

C. Kumara, D. N. Leonard, H. M. Meyer, H. Luo, B. L. Armstrong, and J. Qu, “Palladium Nanoparticle-Enabled Ultrathick Tribofilm with Unique Composition,” ACS Appl Mater Interfaces, vol. 10, no. 37, pp. 31804–31812, Sep. 2018, doi: 10.1021/acsami.8b11213.

S. Zhang, L. Hu, D. Feng, and H. Wang, “Anti-wear and friction-reduction mechanism of Sn and Fe nanoparticles as additives of multialkylated cyclopentanes under vacuum condition,” Vacuum, vol. 87, pp. 75–80, Jan. 2013, doi: 10.1016/j.vacuum.2012.07.009.

J. Padgurskas, R. Rukuiza, I. Prosyčevas, and R. Kreivaitis, “Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles,” Tribol Int, vol. 60, pp. 224–232, Apr. 2013, doi: 10.1016/j.triboint.2012.10.024.

J. M. Liñeira del Río, E. R. López, and J. Fernández, “Synergy between boron nitride or graphene nanoplatelets and tri(butyl)ethylphosphonium diethylphosphate ionic liquid as lubricant additives of triisotridecyltrimellitate oil,” J Mol Liq, vol. 301, p. 112442, Mar. 2020, doi: 10.1016/j.molliq.2020.112442.

J. M. Liñeira del Río, E. R. López, and J. Fernández, “Tribological properties of graphene nanoplatelets or boron nitride nanoparticles as additives of a polyalphaolefin base oil,” J Mol Liq, vol. 333, Jul. 2021, doi: 10.1016/j.molliq.2021.115911.

O. N. Çelik, N. Ay, and Y. Göncü, “Effect of Nano Hexagonal Boron Nitride Lubricant Additives on the Friction and Wear Properties of AISI 4140 Steel,” Particulate Science and Technology, vol. 31, no. 5, pp. 501–506, Sep. 2013, doi: 10.1080/02726351.2013.779336.

Y. Wang, Z. Wan, L. Lu, Z. Zhang, and Y. Tang, “Friction and wear mechanisms of castor oil with addition of hexagonal boron nitride nanoparticles,” Tribol Int, vol. 124, pp. 10–22, Aug. 2018, doi: 10.1016/j.triboint.2018.03.035.

H. Baş and Y. E. Karabacak, “Investigation of the Effects of Boron Additives on the Performance of Engine Oil,” Tribology Transactions, vol. 57, no. 4, pp. 740–748, Jul. 2014, doi: 10.1080/10402004.2014.909549.

T. Akbiyik, N. Kahraman, and T. Taner, “Investigation of the effect of boron additive to lubricating oil on engine performance, exhaust, and emissions,” Fuel, vol. 312, Mar. 2022, doi: 10.1016/j.fuel.2021.122931.

M. Ilman Hakimi Chua Abdullah, M. Fadzli Bin Abdollah, H. Amiruddin, N. Tamaldin, N. Rashid Mat Nuri, and A. Rafeq Saleman, “The hBN Nanoparticles as an Effective Engine Oil Additive to Enhance the Durability and Performance of a Small Diesel Engine,” Journal of Mechanical Engineering, vol. 1, no. 1, pp. 103–112, 2017.

N. Thachnatharen, M. Khalid, A. Arulraj, and N. Sridewi, “Tribological performance of hexagonal boron nitride (hBN) as nano-additives in military grade diesel engine oil,” in Materials Today: Proceedings, Elsevier Ltd, 2021, pp. 70–73. doi: 10.1016/j.matpr.2021.04.145.

N. Nomède-Martyr, M. Vitulin, H. Joseph, and P. Thomas, “Moringa oil with graphite and hexagonal boron nitride particles as additives for lubrication,” Diam Relat Mater, vol. 124, Apr. 2022, doi: 10.1016/j.diamond.2022.108930.

Q. Wan, Y. Jin, P. Sun, and Y. Ding, “Tribological behaviour of a lubricant oil containing boron nitride nanoparticles,” in Procedia Engineering, Elsevier Ltd, 2015, pp. 1038–1045. doi: 10.1016/j.proeng.2015.01.226.

S. Senyk, A. Chodkiewicz, K. Gocman, B. Szczęśniak, and T. Kałdoński, “Hexagonal Nano and Micro Boron Nitride: Properties and Lubrication Applications,” Materials, vol. 15, no. 3, Feb. 2022, doi: 10.3390/ma15030955.

Yanmar, “Yanmar TF Series.” Accessed: Dec. 30, 2022. [Online]. Available: https://www.yanmar.com/en_id/engine/products/diesel/h_watercooled/tfseries/

Y. Ali and M. A. Hanna, “Durability Testing of A Diesel Fuel, Methyl Tallowate, And Ethanol Blend In a Cummins N14-410 Diesel Engine,” Transactions of the ASAE, vol. Vol. 39(3), pp. 793–797, 1996.

C. L. Peterson, J. C. Thompson, and J. S. Taberski, “One-Thousand-Hour Engine Durability Test With Hysee And Using A 5x-EMA Test Cycle,” Transactions of the ASAE, vol. VOL. 42(1), pp. 23–30, 1999.

S. Sae, M. Ziejewski, H. J. Goettler, H. Haines, and C. Huang, “EMA Durability Tests on High Oleic Sunflower and Safflower Oils in Diesel Engines,” 2018.

A. Z. M. Fathallah and F. Pinto, “The Influence of NaCl dissolved on biodiesel of used cooking oil on performance and its degradation of main components of diesel engine,” IOP Conf Ser Earth Environ Sci, vol. 972, no. 1, p. 012030, Jan. 2022, doi: 10.1088/1755-1315/972/1/012030.

K. Nantha Gopal and R. Thundil Karuppa Raj, “Effect of pongamia oil methyl ester-diesel blend on lubricating oil degradation of di compression ignition engine,” Fuel, vol. 165, pp. 105–114, Feb. 2016, doi: 10.1016/j.fuel.2015.10.031.

J. S. Evans, “Where Does All That Metal Come From?,” WearCheck Technical Bulletin Issue 47, 2010.

A. Kotia, S. Borkakoti, and S. K. Ghosh, “Wear and performance analysis of a 4-stroke diesel engine employing nanolubricants,” Particuology, vol. 37, pp. 54–63, Apr. 2018, doi: 10.1016/j.partic.2017.05.016.

Yanmar, Yanmar Service Manual: TF Series. Tokyo. Accessed: Dec. 30, 2022. [Online]. Available: https://www.yanmar.com/media/id/com/maintenance/catalog/100495.pdf

Bureau for Chemical Substances, “ CLH Report For Boric Acid,” Lodz, Poland, 2013.

M. Waqas, R. Zahid, M. U. Bhutta, Z. A. Khan, and A. Saeed, “A review of friction performance of lubricants with nano additives,” Nov. 01, 2021, MDPI. doi: 10.3390/ma14216310.

Unduhan

Diterbitkan

Cara Mengutip

Terbitan

Bagian

Lisensi

Hak Cipta (c) 2025 M Faizur Rijal Azhad

Artikel ini berlisensi Creative Commons Attribution 4.0 International License.