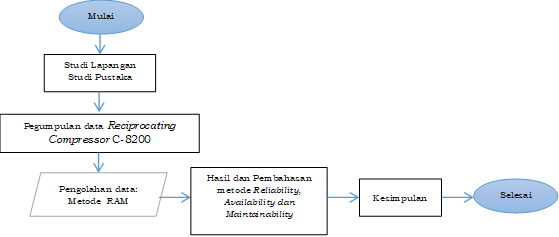

Analisis Pemeliharaan Aset dengan Metode RAM pada Unit Reciprocating Compressor C-8200

DOI:

https://doi.org/10.55679/pistonjt.v10i1.94Keywords:

Reliability , Availability , Maintainability , Maintenance , RAMAbstract

The oil and gas industry becomes an important industry for the community. The need to support survival is production carried out by the company. The company has an obligation when providing the services to the community by producing quality output. To produce good and high-quality results, one of the supporting factors is the existence of qualified production machine units that are able to operate optimally. With a planned machine maintenance system, it minimizes the occurrence of machine failures where the level of machine failure in production is very possible so that the unreliability of a machine can also occur. Therefore, the company must implement a maintenance system with an appropriate method to control the rate of machine failure. The Reciprocating Compressor C-8200 Unit is used as one of the other compressors in operations which of course has failures and also unplanned downtime. Minimizing the risk of failure in the unit, the research was conducted determining the extent to maintenance the assets with RAM Method on the Reciprocating Compressor C-8200 Unit, It has been carried out and this is also to introduce the company to the use of this method.

Downloads

References

Anisya Permata, A.. Analisis Overall Equipment Effectiveness (Oee) Pada Paper Making Machine Dan Pendekatan 5 Whys Untuk Perbaikan Pada PT.Indah Kiat Pulp & Paper Perawang (Studi Kasus: PT.Indah Kiat Pulp & Paper Perawang), Industrial Engineering Online Journal, vol.12, no.1, 2023.

A.Fauzi dan R.Hermawan. Analisa Unjuk Kerja Kompresor Reciprocating Kapasitas 1m3/s Terhadap Perubahan Volume Variable Clearance Pocket (VVCP). Prosiding SENIATI 2018.Vol.4.No.1., 235-238. 2018. https://doi.org/10.36040/seniati.v4i1.789

A.Firman Yusra, E.Budiasih, A.Pamoso, Analisis Performance Mesin Weaving pada PT Abc Menggunakan Metode Reliability Availability Maintainability (Ram) Dan Overall Equipment Effectiveness (OEE). Vol. 5 No. 2, 2535-2543. 2018.

E.S.Sujatman, F.T.D.Atmaji, N.A.Supratman. Performance Assessment Berbasis Reliability Menggunakan Metode Reliability, Availability, Maintainability (Ram) Dan Cost Of Unreliability (Cour) Pada Mesin Cincinnati Milacron Di Direktorat Aerostructure PT Dirgantara Indonesia. e-Proceeding of Engineering, Vol.3, No.2, 2478-2484. 2016.

F.Corvaro, G.Giacchetta, B.Marchetti, M.Recanati. Reliability, Availability, Maintainability (RAM) Study, On Reciprocating Compressors API 618. Vol.3, Issue 2, 266-272,2017.

Gao,S.,& Wang,J.). Reliability And Availability Analysis Of A Retrial System With Mixed Standbys And An Unreliable Repair Facility. Reliability Engineering & System Safety, 205, 107240.2021.

H.I.Akbari, J.Alhilman, A.Pamoso. Analisis Performansi Dan Biaya Perawatan Mesin Menggunakan Metode Reliability, Availability, And Maintainability (Ram) Dan Cost Of Unreliability (Cour) Pada Mesin Lean Carbonate Circulation Pump Di PT. XYZ. e-Proceeding of Engineering, Vol.7, No.2, 5284-5293, 2020.

H.Winarno dan Susilonoto, Analisis Total Productive Maintenance untuk Peningkatan Efisiensi Produksi dengan Menggunakan Metode Overall Equipment Effectiveness di PT. Purna Baja Harsco. Prosiding Seminar Nasional XI “Rekayasa Teknologi Industri dan Informasi 2016 Sekolah Tinggi Teknologi Nasional Yogyakarta. 304-312. 2016.

I.Sukendar. Analisa Kebijakan Sistem Penggantian Cutting Tool Dengan Metode Reliability Availability Maintainability (RAM) Dan Maintenance Value Stream Mapping (MVSM) Di Area Machining NR Crankshaft Pada PT. MMN. Vol.15, No.0 . 2020.

J.B.Pahli. dkk. Buku Sustainable Innovation For Better Oil And Gas Production. pp.39-40, Pertamina. 2023.

N. Fatma, H. Ponda, and R. Kuswara, “Analisis Preventive Maintenance Dengan Metode Menghitung Mean Time Between Failure (Mtbf) Dan Mean Time To Repair (Mttr) (Studi Kasus PT. Gajah Tunggal Tbk)”, Heuristic, vol. 17, no. 2, pp. 87-94, Oct. 2020.

M.Pasau and M. Hetharia, “Analisis Daya Pada Kompresor Reciprocating 3K-O1-B Tpye P 116H 280csh Di Pertamina Unit VI KASIM”, jvoe, vol. 7, no. 2, pp. 61-68, Dec. 2022.

R.F.Stapelberg. Handbook of Reliability, Availability, Maintainability and Safety in Engineering Design. 43-527. 2009.

Smith, David J. Reliability Maintainability and Risk. USA: Elsevier ltd Eighth Edition. 2011.

S.Lestari, S.H.Sa’diyah, Z.Muttaqien. Pengukuran Efektivitas Mesin Cartoning Pada Proses Pengemasan Produk Dengan Pendekatan Overall Equipment Effectiveness (OEE). Motor Bakar: Jurnal Teknik Mesin Universitas Muhammadiyah Tangerang, Vol. 8, No. 2, 2024.

U.Wiharja, dan S.W.Groho. Analisis Efisiensi Daya Motor Induksi 3 Fasa Dengan Menggunakan Soft Starter Pada Reciprocating Compressor. Jurnal Elektro Vol.10, No.1. pp.32-42. 2022.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Rachmasari Pramita Wardhani, Lukman

This work is licensed under a Creative Commons Attribution 4.0 International License.