Extraction of Natural Fibers for Composite Material Applications Using Decorticator Machines

DOI:

https://doi.org/10.55679/pistonjt.v9i1.54Keywords:

Decorticator, Natural Fiber, Composite Material, Design, ExctractionAbstract

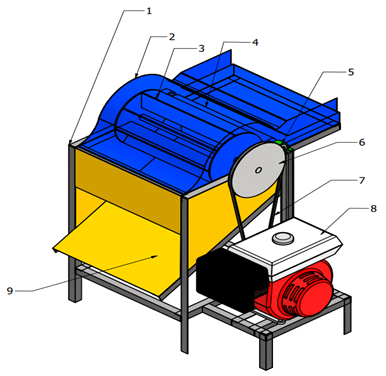

Natural fibers have advantages compared to synthetic fibers because they are biodegradable and sustainable. The problem with natural fibers is the extraction or separation process of the skin and fiber. This research aims to design a decorticator that separates leather and natural fibers to be used as composite reinforcing materials. The procedure for creating a decorticator machine is carried out by collecting initial data and requirements about the decorticator machine, determining effective decorticator machine technology and mechanisms, designing concepts and mechanisms, and planning detailed drawings. From this research, a decorticator design was created with a frame component that functions as the primary support for the machine components; the beater shaft functions to scrape the stem by moving quickly and breaks the outer layer of the stem so that the fibers can be separated, the rolling cylinder functions to hold the fiber during the process of separating the fiber and stem, the machine cover functions to provide safety during operation, the petrol motor as the driving force, and the pulley-belt transmission system. Apart from separating fiber from non-fiber parts, decorticator machines can also increase the use of environmentally friendly natural fibers as composite materials and reduce dependence on synthetic materials.

Downloads

References

Faisal Ahmad, Ardin Wiranata, Jabal Nur, and Syukur Muzakkir, “Rancang Bangun Mesin Penyerut Es Batu”, Piston-JT, vol. 8, no. 2, pp. 01–05, Dec. 2023. https://doi.org/10.55679/pistonjt.v8i2.43

N. Endriatno and L. O. A. Barata, “Rancangan Mesin Pengayak Pasir dengan Konversi Sistem Gerak Rotasi menjadi Translasi”, Piston-JT, vol. 8, no. 1, pp. 23–29, Jun. 2023. https://doi.org/10.55679/pistonjt.v8i1.41

W. D. Callister, JR., D. G. Rethwisch, Material Science And Engineering An Introduction Tenth Edition, Wiley, USA, 2018.

J.P Yadav, D. Kumar, “Design, Fabrication, and Performance Evaluation of Power Operated Groundnut Decorticator,” International Journal of Engineering Research and Technology (IJERT), ISSN: 2278-0181, Vol. 11, No. 02, Naret, 2022.

N. Weisdiyanti dan K. Santoso, “Rancang Bangun Mesin Decorticator Serat Daun Nanas ,” Jurnal Geliga Sains, Vol. 7, no. 1, pp. 18-23, 2019.

M. Qadri,” Analisis Performansi Modifikasi Roll Penyerut Mesin Pengolah Daun Nanas Menjadi Serat” Skripsi, Program Studi Teknik Pertanian Jurusan Teknologi Pertanian, 2024

S. Soeprijanto, N. Fajar Puspita, “’Pengolahan Serat Nanas Menjadi Material Komposit di Desa Satak Kabupaten Kediri,” Jurnal Pengabdian Kepada Masyarakat-LPPM ITS, Vol. 6, No. 4, 2022.

Nanang Endriatno, ”Analisa Pengaruh Variasi Fraksi Volume Terhadap Densitas dan Kekuatan Tarik Serat Pelepah Pisang-Epoksi,” Dinamika Jurnal Ilmiah Teknik Mesin , Vol. 6,no. 2, 2015.

R. S. Khurmi dan J.K. Gupta, A Textbook of Machine Design, Eurasia Publishing House (PVT), 2005.

Sularso dan K. Suga, Dasar Perencanaan dan Pemilihan Elemen Mesin , Jakarta: PT Pradnya Paramita, 1997.

G. Martin, Kinematics and Dynamics of Machines , Mc Graw-Hill Ltd, 2004.

R. J. Smallman, R.E., Bishop, Metalurgi Fisik Modern dan Rekayasa Material, Jakarta: Erlangga, 2000.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Piston: Jurnal Teknologi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.