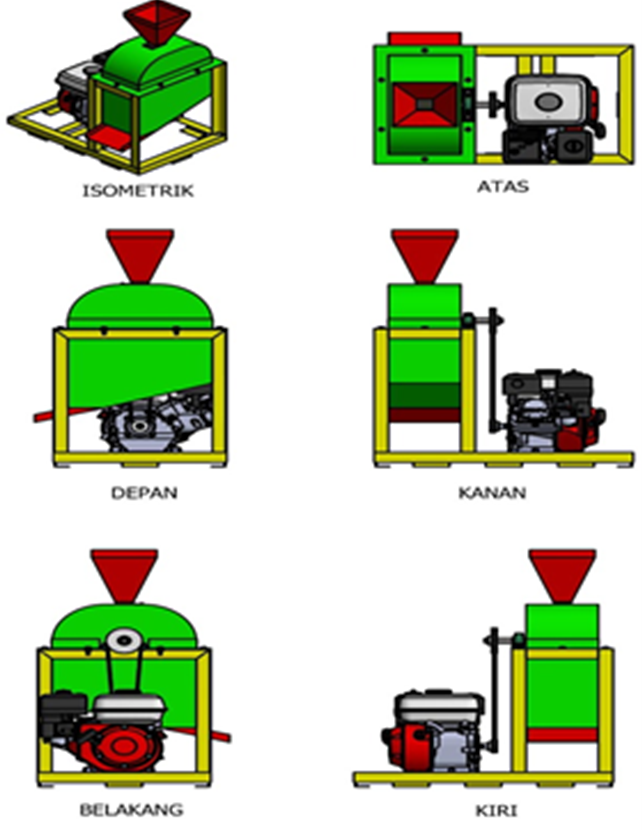

Perancangan Dan Pembuatan Mesin Penghalus Sekam Padi

DOI:

https://doi.org/10.55679/pistonjt.v8i1.26Keywords:

Husk, Rice Husk, Grinding Machine, Agriculture Waste, BladeAbstract

Rice husk is a waste from rice milling that can be utilized by most people, because rice husk contains nutrients and protein. Therefore, this rice husk has many uses, one of which is used as animal feed. To make it animal feed, it requires processing in a puree way so that it is easily digested by the livestock. Seeing this problem, it is necessary to make a rice husk smoothing machine. The working principle of the rice husk smoothing machine is carried out by inserting the rice husk into the inlet funnel which will be refined by the blade, then utilizing the gasoline motor as the prime mover, where the rotation of the machine is continued by a main shaft circuit consisting of 10 blades, the shaft with a diameter of 19 mm, a bearing size of 2.5 inches, V-belt type A 41, and a pulley diameter of 10 cm, as the main components of the rice husk smoothing machine. The capacity of the rice husk smoothing machine is 2400 kg within 8 hours/day of machine operation. The results of grinding the husks within 2 minutes of testing can grind an average of 0.90 kg of fine husks with a rotation of 4815 rpm. So in a day the rice husk smoothing machine can refine 2400 kg in 8 hours or a day of machine operation.

Downloads

References

Arsa, s. 2015 “ pengertian pakan ternak “, ilmu ternak.com/2016/08/pengertian-pakan-ternak.html, diakses pada 20 september 2022 pukul 01.22

Baidilah, A. dkk, “Rancang Bangun Mesin Penggiling Sekam Padi Menjadi Bahan Pakan Ternak” (Dedak), Vol. 14 No. 1 (2021) 22 – 26

Prasetyo, (2018) “Gambar Mesin Penggiling Sekam”, yogyakarta

Sutanto, “Pengolahan Padi Menjadi Beras Melalui Mesin Milling”, (2018)

Sukma, H. dkk, “Perancangan Mesin Penggiling Sekam Padi”, Volume 9 Nomor 2, Juli – Desember (2021), 23-24

Shadewa, D. Dkk, “Pengaruh Komposisi Bahan Dasar Dan Variasi Jenis Perekat Terhadap Nilai Kalor, Kadar Air, Kadar Abu Pada Briket Campuran Sekam Padi Dan Tempurung Kelapa”, Hal 1-10 (2018)

Sularso, (1991) “dasar perancangan dan pemilihan elemen mesin”,PT. Pradnya paramita; jakarta

Widyanugraha, A. dkk, “Perancangan Mesin Penggiling Padi dan Penepung Sekam Padi Skala Rumah Tangga”, Vol. 13 No. 2 (2020) 69 -75

Wibawa, R. “Pengaplikasian Pulley Serta Penjelasannya”, (2018)

Yulianto, A. “Pengertian Motor Bakar Atau Mesin Bensin”, (2018)

F. Amelia, W. Zulkaidah, S. Hay, F. E. Larobu, A. Lolok, and Abd.Kadir, “Alat Pencacah Pakan Ternak Menggunakan Motor Universal”, Piston-JT, vol. 7, no. 1, pp. 41–45, Jun. 2022.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Piston: Jurnal Teknologi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.