Analisis Kebutuhan Energi dari Minyak Goreng Bekas menjadi Bahan Bakar Biodiesel B40, B60, dan B80 menggunakan Kompor Minyak Bekas

DOI:

https://doi.org/10.55679/pistonjt.v10i1.109Keywords:

Oil stove , Biodiesel , Transesterification , Used cooking oil , EnergyAbstract

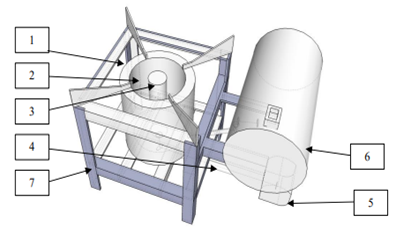

Stoves that use used oil as fuel are widely used as a tool to utilize liquid waste such as oil into fuel. The aim of this study is focused on comparing the energy requirements and efficiency of various fuels sourced from used cooking oil through transesterification. This research utilizes used cooking oil as an alternative fuel using a used oil stove. Waste cooking oil is processed into biodiesel fuel through a transesterification process into three variations, B40, B60, and B80. Testing of fuel variations on used oil stoves showed that the energy requirement value for B40 fuel had a higher value (0.27 kcal/second) than B60 fuel (0.22 kcal/second) and B80 fuel (0.18 kcal/second). The results shown for the combustion efficiency of B40 fuel have a higher average value (18.9%) than B60 fuel (17.2%) and B80 fuel (14.9%). This shows that the percentage of transesterification results of a mixture of used cooking oil and diesel fuel that is increasing, is seen to experience a decrease in the value of energy requirements and combustion efficiency. The highest combustion efficiency value is found in B40 fuel which has a mixture percentage of 40% transesterification oil and 60% diesel fuel. There was a decrease in combustion efficiency of 8.9% from B40 fuel to B60 fuel, and a decrease in combustion efficiency of 21.2% from B40 fuel to B80 fuel.

Downloads

References

Aziz, "Uji Performance Mesin Diesel Menggunakan Biodiesel Dari Minyak Goreng Bekas", Jurnal Kimia Valensi, vol. 1, No. 6, 2010. DOI: 10.15408/jkv.v1i6.241.

Fadhillah, G. N., & Sari, D.A, "Produksi biodiesel Yang Berbahan Baku Kelapa Sawit Katalis Homogen Dan Heterogen", Jurnal Ilmu Pengetahuan Dan Teknologi, 37: 87–94, 2023. DOI: 10.31941/jurnalpena.v37i2.2484.

Kusnadi, A. Djafar, R. & Mustofa, "Pemanfaatan Oli Bekas Sebagai Bahan Bakar Alternatif Kompor Yang Ramah Lingkungan", J. Teknol. Pertan. Gorontalo, vol. 5, no. 2, pp. 49–55, 2020. DOI: 10.30869/jtpg.v5i2.681.

Mahardika, K. E. Santoso, D. T. Kasiadi, K, "Pengaruh Kecepatan Udara Dan Debit Bahan Bakar Pada Pembakaran Burner Berbahan Bakar Oli Bekas", Jurnal Teknik Mesin ITI, vol. 4, No. 3, 2020. DOI: 10.31543/jtm.v4i3.451.

Mulyana, I. S, "Analisis Aliran Udara Pada Pipa Kompor Burner", Jurnal Teknik dan Science, vol. 3, no. 2, pp. 66-76, 2024. DOI: 10.56127/jts.v3i2.1532.

PERTAMINA, "Bagaimana Biosolar B30 Dibuat", 2022. Diakses Februari, 2025, dari https://onesolution.pertamina.com/Insight/Page/Bagaimana_Biosolar_B30_Dibuat.

Ramadhan, G. W. & Basyirun, "Pengaruh Tekanan Udara Terhadap Temperatur Pembakaran Oli Bekas Pada Kompor", Jurnal Dinamika Vokasional Teknik Mesin, vol. 5, no. 2, pp. 163-168, 2020.

Susilo, B. Damayanti, R. Izza, N, Teknik Bioenergi, Malang: UB Press, 2017.

Suwarto & Basri, H, "Pengaruh Pencampuran Bahan Bakar Biosolar Dan Dexlite Terhadap Opasitas Gas Buang Dan Konsumsi Bahan Bakar Pada Internal Combustion Engine (ICE) ", Prosiding SENIATI, pp. 184-192, 2018.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 La Atina, Afdal Syarif, Muhammad Iqbal Achmad, La Baride, Dedy Ashari

This work is licensed under a Creative Commons Attribution 4.0 International License.