Analisis Kekuatan Rangka Mesin Pencacah Nilam dengan Menggunakan Metode Elemen Hingga

DOI:

https://doi.org/10.55679/pistonjt.v9i2.74Keywords:

Frame Strength, Simulation , Force, Displacement, SafetyAbstract

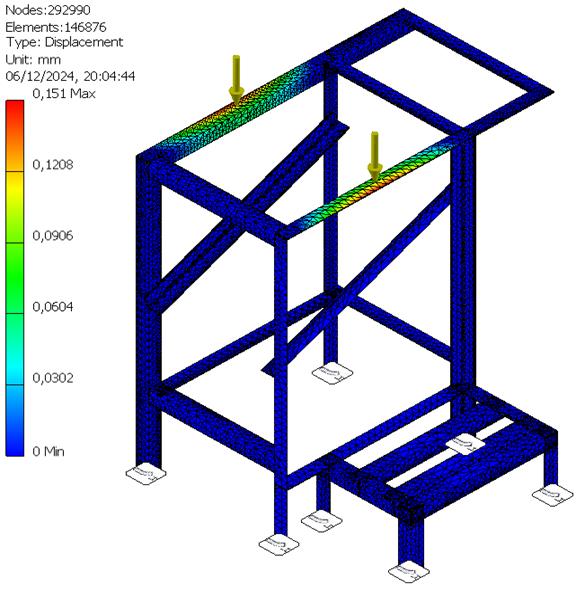

Frames are often used as essential elements in the construction of machines and various other engineering products. The strength of the frame is significant in ensuring that the structure can withstand operational loads when used. Frame failure can cause severe damage, accidents, and substantial financial losses, so evaluating the strength of the frame before production is a critical step in the design process. This study aims to analyze the mechanical behavior of the components or frames of the patchouli chopping machine based on the maximum stress, displacement, and safety factor of the designed frame. The research method using finite element simulation technology is an efficient approach to analyzing the performance of frame structures. By utilizing simulations, a comprehensive evaluation of various parameters such as stress, displacement, and frame safety can be carried out. This process helps predict the structure's response to multiple loads received by the system. The simulation results using the finite element method show that the L-profile frame 40x40x3 mm with a cross-sectional area of 307.863 mm2 can withstand a maximum load of 1000 N with a maximum deformation of 0.2479 mm, which occurs at the load center. The von Mises stress distribution shows that the stress that occurs in the L-profile steel is 28.8 MPa. This value is far below the material yield strength threshold of 207 MPa. The maximum Safety Factor value that occurs in the frame is 15 ul, and there is no safety factor value below 1. The simulation results show that the analyzed frame is safe and meets the specified design requirements

Downloads

References

Ahmad Syahrizal Hamdani, Zetyawan Ardan, Muh. Maftuh, and Krismon La Maru, “Perancangan Mesin Penggiling Jagung untuk Pakan Ternak,” Pist. J. Teknol., vol. 8, no. 2, pp. 06–13, Dec. 2023, doi: 10.55679/pistonjt.v8i2.44.

Sularso., Dasar Perencanaan Dan Pemilihan Elemen Mesin. Jakarta: PT. Pradnya Paramita, 2002.

D. J. Perkebunan, “Patchouli.,” in Nilam (Patchouli), 2019th ed., Jakarta: Direktorat Jenderal Perkebunan, 2019, pp. 198–208. doi: 10.1079/9781780645599.0198.

M. Miswan, S. Salimin, and N. Endriatno, “Desain dan Analisa Mesin Pencacah Nilam Dengan Kapasitas 200 Kg/Jam,” Enthalpy J. Ilm. Mhs. Tek. Mesin, vol. 6, no. 4, p. 175, 2021, doi: 10.55679/enthalpy.v6i4.22573.

F. Prananda, R. Balaka, and N. Endriatno, “Analisis Perancangan Alat Pencacah Nilam Untuk Petani Nilam,” Enthalpy J. Ilm. Mhs. Tek. Mesin, vol. 9, no. 1, p. 13, 2024, doi: 10.55679/enthalpy.v9i1.46935.

N. Endriatno et al., “Pengenalan Mesin Pencacah Untuk Membantu Petani Nilam Di Desa Aoma Kecamatan Wolasi Kabupaten Konawe Selatan,” Jurnal Pengabdian Masyarakat Ilmu Terapan, vol. 5, no. 2. pp. 141–147, 2023.

E. A. Avallone and T. B. Iii, Marks’ standard handbook for mechanical engineers, vol. 34, no. 06. 1997. doi: 10.5860/choice.34-3330.

R. S. Khurmi and J. K. Gupta, “A Textbook of Machine Design. Ram Nagar: Eurasia Publishing House (PVT),” Engg. Serv., no. I, pp. 1–200, 2005.

A. Purkuncoro, Eko, Pengenalan computer aided design 2d / 3d Assembly dan Animate menggunakan Autodesk Inventor Professional. Malang: Universitas Wisnuwardhana Malang Press (Unidha Press), 2019.

L. A. N. Wibawa, Simulasi Kekuatan Komponen Sarana Pengujian Roket Menggunakan Autidesk Inventor Professional 2017. Garut: bukuKatta, 2018.

D. L. Logan, A first course in the finite element method, vol. 3, no. 2. Toronto: University of Wisconsin–Platteville, 1987. doi: 10.1016/0168-874x(87)90008-4.

A. Toteles and F. Alhaffis, “Analisis Material Kontruksi Chasis Mobil Listrik Laksamana V2 Menggunakan Software Autodesk Inventor,” Mach. J. Tek. Mesin, vol. 7, no. 1, pp. 30–37, 2021.

R. M. Putra, “Analisa Kekuatan Rangka Mesin penghalus Arang Tempurung Kelapa Menggunakan Software Autodesk Inventor Student 2024,” vol. 2, no. 1, pp. 130–144, 2024.

B. Setyono, “Perancangan Dan Analisis Kekuatan Frame Sepeda Hibrid ‘Trisona’ Menggunakan Software Autodesk Inventor,” J. IPTEK, vol. 20, no. 2, p. 37, 2016, doi: 10.31284/j.iptek.2016.v20i2.43.

L. A. N. Wibawa, “Desain Dan Analisis Tegangan Crane Hook Model Circular Section Kapasitas 5 Ton Menggunakan Autodesk Inventor 2017,” Simetris J. Tek. Mesin, Elektro dan Ilmu Komput., vol. 10, no. 1, pp. 27–32, 2019, doi: 10.24176/simet.v10i1.2669.

M. Aswan, I. P. S. Negara, and I. G. O. Pujihadi, “Analisis Tegangan Pada Design Frame Mini Crane Portable Menggunakan Software Autodesk Inventor,” Semin. Nas. Terap. Ris. Inov. Ke-XX, vol. 7, no. 1, pp. 9–16, 2021.

Eko Susetyo Yulianto, Doddi Yuniardi, Achmad Risa Harfit, and Candra Adi Setyawan, “Analisis Pulley Pada Mesin Pencacah Kaleng Bebantuan Software Solidworks,” J. Ilm. Tek., vol. 3, no. 2, pp. 49–61, 2024, doi: 10.56127/juit.v3i2.1432.

Eko Aprianto Nugroho and Abdul Rahman Agung Ramadhan, “Desain Dan Analsis Rangka Pada Mesin Pengupas Biji Kopi Basah Menggunakan Software Solidworks,” J. Tek. dan Sci., vol. 2, no. 2, pp. 16–22, 2023, doi: 10.56127/jts.v2i2.762.

S. Khoiriah, “Desain Dan Analisis Kekuatan Pada Ladder,” Universitas Negeri Semarang, Semarang, 2020.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Piston: Jurnal Teknologi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.