Uji Eksperimental Aliran Dalam Pipa dengan Variasi Rangkaian Pompa Sentrifugal

DOI:

https://doi.org/10.55679/pistonjt.v9i1.57Keywords:

pump, series, parallel, flow rate, efficiency, Pump, Series, Parallel, Flow rate, EfficiencyAbstract

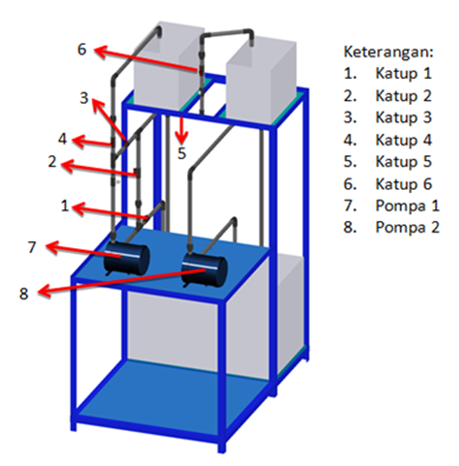

A pump converts the rotational energy of the shaft and subsequently the movement of the blades into kinetic energy and pressure in the fluid. Pumps can be configured as single, double series, or double parallel, depending on the requirements. This research aims to determine the best performance of a centrifugal pump installation with variations in head and configuration. The method used in this research is experimental, utilizing a centrifugal pump arranged with water as the fluid. The results show that single and double series configurations are more suitable for applications requiring stable flow despite changes in head. Parallel configurations produce higher speeds compared to single and double series configurations, but speed decreases with increasing head. The single pump's efficiency increases to 40.5% with an increase in head. Efficiency in the series configuration increases to 50.1%, higher than the single pump at the same head. Efficiency in the double parallel configuration increases to 80.1%, indicating that the parallel pump is the most efficient at higher heads. For applications requiring high efficiency, the double parallel pump configuration is the best choice. Based on the analysis results, it can be concluded that the double parallel pump configuration provides the best performance with the highest efficiency at 80.1%, and the highest discharge rate of 43.2 l/min. The double parallel pump configuration is the most efficient and effective for applications requiring optimal pump performance at higher heads.

Downloads

References

Salimin and L. O. A. Barata, “Perancangan dan Pengujian Pompa Hidram ”, Piston-JT, vol. 6, no. 2, pp. 11–22, Dec. 2021, https://doi.org/10.55679/pistonjt.v6i2.35.

S. Wuryanti, M. Maridjo, S. Slameto, I. Yuliyani, and I. Indriyani, “Perbandingan Karakteristik Pompa Tunggal dengan Pompa Ganda yang Dioperasikan secara Seri maupun Paralel,” J. Rekayasa Mesin, vol. 18, no. 2, p. 147, 2023, doi: 10.32497/jrm.v18i2.3967.

Haruo Tahara and Sularso, Pompa dan Kompresor. Jakarta: PT.Pradnya Paramita, 2000.

E. Repsa and E. Kronbergs, “Investigation of Centrifugal Pump Characteristics,” Jelgava, vol. 20, no. Lcc, pp. 551–556, 2021, doi: 10.22616/ERDev.2021.20.TF119.

Y. R. Adhari and A. Akhyan, “Studi Eksprimental Pengaruh Kinerja Pompa Sentrifugal Seri Dan Paralel Menggunakan Fluida Crude Palm Oil (Non Newtonian),” Proceeding Appl. Bus. Eng. Conf., no. November, pp. 17–19, 2022.

Y. Guan, M. Bai, X. Meng, Y. Liu, and F. Xu, “Experimental investigation of Piezoelectric Micropumps with Single, Series or Parallel Pump Chambers,” Int. J. Acoust. Vib., vol. 25, no. 3, pp. 453–460, 2020, doi: 10.20855/ijav.2020.25.31688.

S. J. Olson, R.M. and Wright, Dasar-Dasar Mekanika Fluida. Jakarta: Erlangga, 1990.

J. B Manga, Dasar-dasar Pompa dan Perencanaan. Ujung Pandang, 1990.

C. Himawan, J. W. Dika, and A. D. Putra, “Analisis Pengaruh Variasi Katup Tetap RPM Berubah Dan Variasi RPM Tetap Katup Berubah Pada Pompa Seri, Pararel, dan Tunggal,” Ring Mech. Eng. (RING ME), vol. 3, no. 2, pp. 105–112, 2023, doi: https://doi.org/10.33474/rm.v3i1.

Shivani Kaustubh Chitale, Pranjal Nitin Jadhav, Snehal Suresh Dhoble, and Dr. Mr. Satyajeet Deshmukh, “Parameters Affecting Efficiency of Centrifugal Pump - A Review,” Int. J. Sci. Res. Sci. Technol., pp. 49–58, 2021, doi: 10.32628/ijsrst218573.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Piston: Jurnal Teknologi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.