Perancangan Mesin Pencacah Rumput Pakan Ternak Menggunakan Sistem Penggerak Motor Listrik

DOI:

https://doi.org/10.55679/pistonjt.v9i1.55Keywords:

Weeds, City Cleanliness, Lawn Mowers, Electric Machines, DesignAbstract

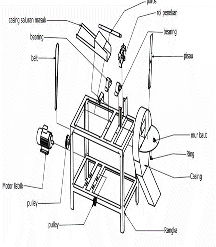

The aim of this final assignment is to design an animal feed grass chopper machine using an electric motor drive system and to determine the production capabilities (on machine activity) of the grass chopper. This machine is a multi-purpose machine as a forage designer, especially used to design animal feed grass. In making this final assignment, the author chose the title of designing an animal feed chopping machine using an electric motor system to save time. Seeing that there are still many people who currently chop animal feed using manual tools and this will require a fairly long process, of course, having an animal feed chopper machine that uses an electric motor can shorten the time in the process of chopping animal feed. Therefore, the creation of this final assignment can make work easier and can save time so that workers can complete it more quickly. The initial process for operating an animal feed chopper is to connect the dynamo cable to an electric current, then take the elephant grass and then insert it into the inlet of the grass chopper. This tool is capable of producing grass chopping of 0.94 grams/1 minute 42 seconds. The driving source of this tool uses a 1/2 HP DC electric motor with a rotation of 2800 rpm. The conclusion of this final project is how to design an animal feed grass chopper consisting of a frame, a dynamo with 220 Volt power and a battery current of 3.54 A. The application used to design this tool is sketchup, the tools and materials used include grinding, meter, welding transformer, welding glasses, electric drill, angle rule, hammer, L profile iron, plate iron and bolts. Test results of the tool and working voltage of 220 Volts, maximum speed of 2800 rpm, chopping results of 0.94 grams/1 minute 42 seconds of operation using a cable from a dynamo to electric current and a 220 Volt power source. Our suggestion is to develop this tool in terms of the transmission system, the engine output rotation is still very large, making the grass chopped results very small. So we need a machine speed control device (variable speed) so that the chopping can be adjusted according to the required speed.

Downloads

References

Umam, K., Putra Munir, A., & Sigalingging, D. R. (2018). RANCANG BANGUN ALAT PENCACAH PELEPAH SAWIT TIPE SERUT (Design of Planer mode Oil Palm Midrib Chopper). In Keteknikan Pertanian J.Rekayasa Pangan dan Pert (Vol. 6, Issue 2).

N. Endriatno and L. O. A. Barata, “Rancangan Mesin Pengayak Pasir dengan Konversi Sistem Gerak Rotasi menjadi Translasi”, Piston-JT, vol. 8, no. 1, pp. 23–29, Jun. 2023. https://doi.org/10.55679/pistonjt.v8i1.41

Erick Patollong, Muh. Rizal Ode, Lukas Kano Mangalla, dan Aminur, “Mesin Penghancur Cangkang Kerang ”, Piston-JT, vol. 8, no. 1, pp. 10–15, Jul. 2023. https://doi.org/10.55679/pistonjt.v8i1.25

Andrian, M., Rala, S., Asmara, S., & Suharyatun, S. (n.d.). PENGARUH KECEPATAN PUTAR TERHADAP UNJUK KERJA MESIN PENCACAH PELEPAH KELAPA SAWIT (CHOPPER)TIPE TEP-1 THE EFFECT OF SPEED ROTATION TO THE PERFORMANCE OF PALM OIL MIDRIB CHOPPER MACHINE TEP-1 TYPE. In Jurnal Teknik Pertanian Lampung (Vol. 6, Issue 3).

Bulan, R., Mandang, T., Hermawan, W., Desrial, D., & Agussabti, A. (2018). Design and Performance of an Integrated Machine for Chopping Oil Palm Leaves and Compressing Fronds. Jurnal Keteknikan Pertanian, 6(1), 1–8. https://doi.org/10.19028/jtep.06.1.83-90

Hasbi Assiddiq S, Asrul, & Pratama Hermanto. (2022). Rancang Bangun Mesin Pencacah Rumput dan Pelepah Kelapa Sawit dengan Penggerak Motor Bensin Sebagai Pakan Ternak. Infotekmesin, 13(2), 212–218. https://doi.org/10.35970/infotekmesin.v13i2.1530

Fitri Arriyani, Y., Dwi Krishnaningsih, S., & Teknik Mesin Politeknik Manufaktur Negeri Bangka Belitung, J. (2021). Kinerja Mesin Pencacah Pelepah Kelapa Sawit Dengan Sistem Rotary. Jurnal Teknologi Manufaktur, 13(02).

Prananda, F., Balaka, R., Endriatno, N., (2024). Analisis Perancangan Alat Pencacah Nilam Untuk Petani Nilam. 9(1), 13–19. http://ojs.uho.ac.id/index.php/ENTHALPY

Randi, H., Sidik, S., Manggalla, K. L., Salimin, (2023). Perancangan dan Pengujian Mesin Spinner Peniris Vertikal Untuk Industri Rumah Tangga Menggunakan Penggerak Motor Listrik. Jurnal Ilmiah Mahasiswa Teknik Mesin, 8(3), 82–88. https://ojs.uho.ac.id/index.php/ENTHALPY/article/view/42772/18840

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Piston: Jurnal Teknologi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.