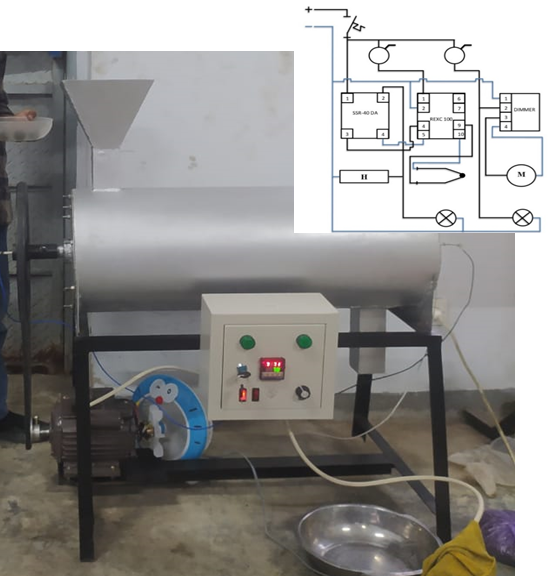

Rancang Bangun Mesin Pengering Skala Miniatur Dengan Kapasitas 0,5 HP

DOI:

https://doi.org/10.55679/pistonjt.v8i1.14Keywords:

Drying, Commodity , Electric motor, Heating rate, Moisture contentAbstract

The need for spices continues to increase in line with the increasing population of the growing industrial world that requires raw materials from nutmeg seeds, the parts that are utilized in nutmeg fruit are mainly the pulp, seed shell, seed coat and fruit flesh. The design of this dryer aims to increase effectiveness and efficiency in the process of drying raw materials in the community. This tool uses an electric motor as the prime mover and uses a panel box as the center of the electrical control device, which contains several components such as a regulator to control the motor speed, an MCB to protect the voltage and other components. The results of testing this tool were quite good, the results of testing the ingredients at a weight of 200-205g in 75 minutes at a temperature of 100°C left a moisture content of 15.62% in nutmeg and 39.28% in candlenut. The cashew test was carried out at a weight of 200-205g in 50 minutes at a temperature of 72.2°C leaving 50.49% moisture content. The cassava test was carried out at a weight of 200-205g in 25-29 minutes at a temperature of 122°C leaving 60.90% moisture content. Testing on corn cobs was carried out at a weight of 200-205g in 25 minutes at a temperature of 119°C with a final weight of 124g. This tool has advantages, namely, it can save drying time, temperature control is easy to do and this tool has been equipped with a current safety device in the event of an electric short circuit. This tool also has drawbacks, namely, it cannot dry raw materials in the form of sheets, slices and powders. The drying tube is not long enough, so a manual continuous cycle is required, for raw materials that require drying time exceeding 25 minutes and requires more electric power.

Downloads

References

Adamsyah, M.S. & Mulyadi, "Perancangan Alat Pengering Kerupuk dengan Menggunakan Pemanas Heater," R.E.M (Rekayasa Energi Manufaktur), vol. 4, no. 1, pp. 27-51, 2019.

A. Rahmat Saleh, M. Ridwan Agung, L. N. Wahyudin, and M. J. Firdaus, “Pengering Cengkeh Menggunakan Oven”, Piston-JT, vol. 7, no. 1, pp. 29–35, Jun. 2022.

Kaplale, R.A., Rawung, H., Tooy, D., "PENGERINGAN BIJI PALA (Myristica fragrans Houtt) MENGGUNAKAN ENERGI RADIASI MATAHARI DAN LPG (Liquefied Petroleum Gas) DENGAN BANTUAN ALAT PENGERING", Cocos, Vol.10, no. 8, 2018.

Majid, A., Kardiman, and Hanifi, R., "Perancangan Alat Bantu untuk Optimalisasi Proses Produksi Sayap Cover Blower di CV. DEF," Jurnal Ilmiah Wahana Pendidikan, vol. 8, no. 12, pp. 25-32, 2022.

Hariri, H., and Nugroho, F.H., "Perancangan Alat Pengering Cengkeh Berkapasitas 30 kg Berbasis Arduino," Teknobiz : Jurnal Ilmiah Program Studi Magister Teknik Mesin, vol. 11, no. 2, pp. 122-128, 2021.

Arhamsyah, M., Syam, H., dan Jamalaudin, "MODIFIKASI MESIN PENGERING DENGAN MEMANFAATKAN UDARA PANAS DARI ELEMEN PEMANAS LISTRIK," Jurnal Pendidikan Teknologi Pertanian, vol. 4, 2018.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Piston: Jurnal Teknologi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.