Rekayasa Material Serat Alternatif Melalui Desain Mesin Pengurai Sabut Kelapa

DOI:

https://doi.org/10.55679/pistonjt.v10i2.126Keywords:

Separator Machine, Coir Fiber Material, Design, MachineAbstract

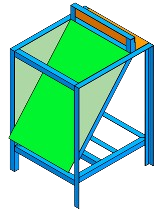

Coconut fiber is a byproduct of the coconut industry that is abundant and has not been utilized optimally. Coconut fiber has good mechanical properties, is environmentally friendly, and has the potential to be used as an alternative fiber material. This study aims to design a coconut fiber decomposing machine that is capable of producing alternative fiber materials. The research methods include literature study, machine mechanism design, and machine design. The machine is designed with a 30x30x3 mm angle profile steel frame measuring 700x500x400 mm in height x length x width, using a decomposing cylinder with a diameter of 164 mm and a length of 355 mm. The decomposing cylinder functions to decompose coconut fiber into fiber. Another main component is the coconut fiber holder plate that functions to clamp the coconut fiber to keep it in position during machine operation. The coconut fiber will be held in the coconut fiber holder, while the other part will fall through the outlet channel. This machine is driven by a 5.5 HP electric motor with a maximum rotation of 1400 rpm. The transmission system uses a belt and pulleys, with a 70 mm input pulley and a 200 mm output pulley, producing a maximum rotation speed of 490 rpm. The design is expected to make a machine capable of increasing the added value of coconut fiber waste and supporting the development of alternative fibers based on natural fibers.

Downloads

References

B. Indonesia, “BPS 2024.” [Online]. Available: https://www.bps.go.id/id/statistics-table/2/MTMyIzI=/produksi-tanaman-perkebunan.html

N. Endriatno, “Review of Characteristics and Mechanical Properties of Coconut Fiber as Reinforcement in Polymer Matrix Composites,” vol. 01, no. 02, 2024.

M. A. Hidalgo-Salazar, J. P. Correa-Aguirre, S. García-Navarro, and L. Roca-Blay, “Injection molding of coir coconut fiber reinforced polyolefin blends: Mechanical, viscoelastic, thermal behavior and three-dimensional microscopy study,” Polymers (Basel)., vol. 12, no. 7, pp. 1–20, 2020, doi: 10.3390/polym12071507.

R. Damian, N. Bifel, E. U. K. Maliwemu, D. G. H. Adoe, and J. T. Mesin, “Pengaruh Perlakuan Alkali Serat Sabut Kelapa terhadap Kekuatan Tarik Komposit Polyester,” LONTAR J. Tek. Mesin Undana, vol. 2, no. 1, pp. 61–68, 2015, [Online]. Available: https://ejurnal.undana.ac.id/index.php/LJTMU/article/view/489

S. M, J. J, D. Azis, and A. Haslinah, “Pengaruh Fraksi Volume Komposit Serat Sabut Kelapa Bermatrik Polimer Termoseting Polyester Terhadap Kekuatan Lentur,” ILTEK J. Teknol., vol. 17, no. 1, pp. 15–19, 2022, doi: 10.47398/iltek.v17i1.703.

Y. Fakhrud, B. Asngali, and A. Wennas, “Studi Karakteristik Komposit Serat Kelapa Terhadap Waktu Perendaman H2so4 dengan Matrik Epoxy Untuk Pembuatan Komponen Kendaraan,” vol. 6, no. 1, pp. 2019–2021, 2021.

D. L. Rizki, Ramadhan, “Pengaruh Variasi Panjang Serat Sabut Kelapa Bermatrik Plastik Recycled High Density Polyethylene (rHDPE) Terhadap Kekuatan Lentur Komposit,” 2023.

W. Apriani and I. F. B. N, “Uji Performansi pada Mesin Pengurai Sabut Kelapa dengan Modifikasi Pisau Pengurai,” vol. 6, no. 2, pp. 57–63, 2022.

H. Priono et al., “Desain Pencacah Serabut Kelapa Dengan Penggerak Motor,” J. Engine, vol. 3, no. 1, 2019.

J. S. Bale, “Material Komposit Polimer Berpenguat Serat,” 2022.

S. Harish, D. P. Michael, A. Bensely, D. M. Lal, and A. Rajadurai, “Mechanical property evaluation of natural fiber coir composite,” Mater. Charact., vol. 60, no. 1, pp. 44–49, 2009, doi: 10.1016/j.matchar.2008.07.001.

E. Vélez et al., “Coconut-Fiber Composite Concrete: Assessment of Mechanical Performance and Environmental Benefits,” Fibers, vol. 10, no. 11, pp. 1–12, 2022, doi: 10.3390/fib10110096.

R. S. Khurmi and J. K. Gupta, “A Textbook of Machine Design. Ram Nagar: Eurasia Publishing House (PVT),” Engg. Serv., no. I, pp. 1–200, 2005.

R. S. KHURMI and J. K. GUPTA, “Handbook of Machinery Dynamics,” Handb. Mach. Dyn., no. 1, pp. 11–28, 2000.

Khurmi and Gupta, “A Textbook of Machine Design,” no. 1, pp. 11–28, 2005, doi: 10.1038/042171a0.

Sularso., Dasar Perencanaan Dan Pemilihan Elemen Mesin. Jakarta: PT. Pradnya Paramita, 2002.

N. Endriatno et al., “Pengenalan Mesin Pencacah Untuk Membantu Petani Nilam Di Desa Aoma Kecamatan Wolasi Kabupaten Konawe Selatan,” Jurnal Pengabdian Masyarakat Ilmu Terapan, vol. 5, no. 2. pp. 141–147, 2023.

N. Endriatno, L. O. A. Barata, and Salimin, “Analisis Kekuatan Rangka Mesin Pencacah Nilam dengan Menggunakan Metode Elemen Hingga”, Piston-JT, vol. 9, no. 2, pp. 56–64, Dec. 2024.

F. Prananda, R. Balaka, and N. Endriatno, “Analisis Perancangan Alat Pencacah Nilam Untuk Petani Nilam,” Enthalpy J. Ilm. Mhs. Tek. Mesin, vol. 9, no. 1, p. 13, 2024, doi: 10.55679/enthalpy.v9i1.46935.

A. Gafur and A. Muklis, “Rancang Bangun Mesin Pengurai Sabut Kelapa Menjadi Cocopeat Dan Cocofiber,” J. Din. Vokasional Tek. Mesin, vol. 7, no. April, pp. 55–61, 2022.

“View of Sosialisasi dan Inovasi Mesin Pengurai Sabut Kelapa Guna Meningkatkan Kualitas dan Produktifitas Industri Sabut Kelapa di Desa Lamnga Kecamatan Mesjid Raya Aceh Besar.pdf.”

S. Subekti et al., “Pelatihan Pengoperasian Mesin Pengurai Sabut Kelapa Di RPTRA Menara Kelurahaan Kembangan Selatan Jakarta Barat,” vol. 3, no. 4, pp. 737–743, 2025.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Nanang Endriatno

This work is licensed under a Creative Commons Attribution 4.0 International License.